Support documentation

General

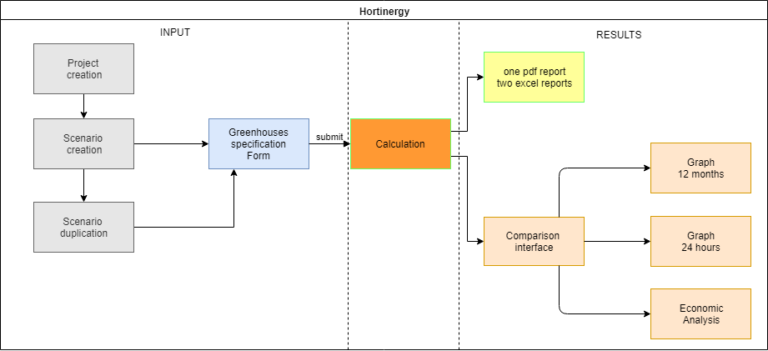

What about results ?

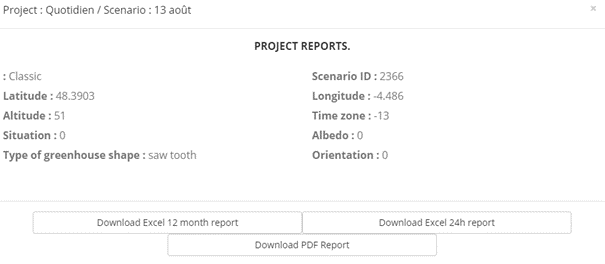

The report is sent to you about 5 minutes after you submitted your form. It is available in PDF format, easy to download. You will receive three reports on your account. These reports contain all the results of the calculation and many specifications about your project.

A PDF report summarizes specifications about your project and let you know:

- Energy consumption for heating,

- Inner climate (temperature, humidity, PAR reaching canopy),

- Energy consumption, cooling and dehumidification,

- PAR reaching canopy and artificial light required to reach day light integral,

- Climate analysis,

- Estimation of greenhouse Gas emitted

You also receive two Excel reports with detailed data:

- Monthly summary

- Hourly values during two typical year

How many greenhouses specification forms

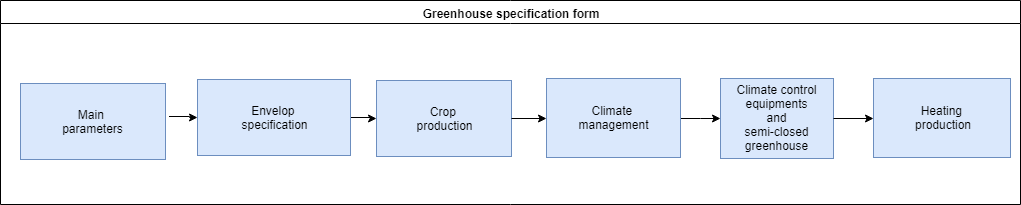

The form, easy to fill out, is divided into 6 parts represented by tabs:

How does Hortinergy work ?

Before you start your project, here are some meanings on the icons on the “profile” page.

A project is the geographical coordinates of your greenhouse. Each variation you make on this project is a scenario.

Innovative algorithms take into account specific greenhouse parameters. Our weather file includes a typical year on an hourly basis based on the GPS coordinates with parameters such as:

- Temperature,

- Relative humidity,

- Wind,

- Solar radiation (global, diffuse, PAR…)

Greenhouse covering includes :

- Type and shade of the greenhouses project (Venlo, gothic…)

- Orientation and dimension,

- Covering materials of each wall,

- Climate screens…

Hortinergy has a large material library. It is updated with the latest branded materials.

Hortinergy also takes into account the crop evapotranspiration. For this purpose, parameters about crop management have to be filled in: crop types, growing medium types, transplanting date and uprooting date, etc…

Hortinergy also considers climate control settings just as a climate computer would do:

- Temperature setpoints and relative humidity control,

- Screen regulation types,

- Morning revival

We can model standard and innovative equipment such as:

- Semi-closed and closed greenhouse,

- Pad and fan,

- Assimilation light (LED, HPS) …

For heat production and storage, hortinergy includes:

- Energy source for primary and secondary systems,

- Heat production and distribution yield,

- Buffer tank: volume, regulation…

Report analysis

Where can I find the report ?

Once, your report is ready, you will be notified by email and you will find the pdf/excel reports by clicking on the “My Projects ” tab.

Form filling

How much time does it take to fill a simulation form ?

It takes between 5 and 15 minutes.

Weather file

Meteonorm

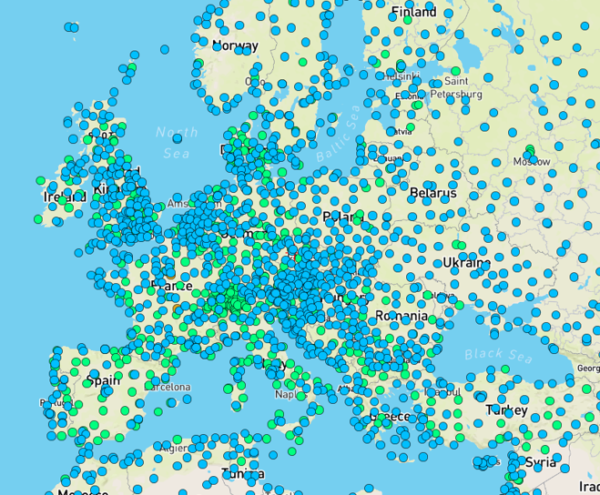

The weather file is generated by Meteonorm based on GPS coordinates of the greenhouse.

Meteonorm is a Swiss software generating weather files, used worldwide by designed of solar plants and buildings.

Meteonorm is embedded inside Hortinergy.

Combining satellite data and interpolation of weather stations, Meteonorm generates weather file for a typical year.

Weather file includes on an hourly basis for a typical year;

- Temperature

- Relative humidity

- Solar radiation: global horizontal, diffuse, normal

- PAR

- Wind direction and velocity

- Sky temperature

- Nebulosity

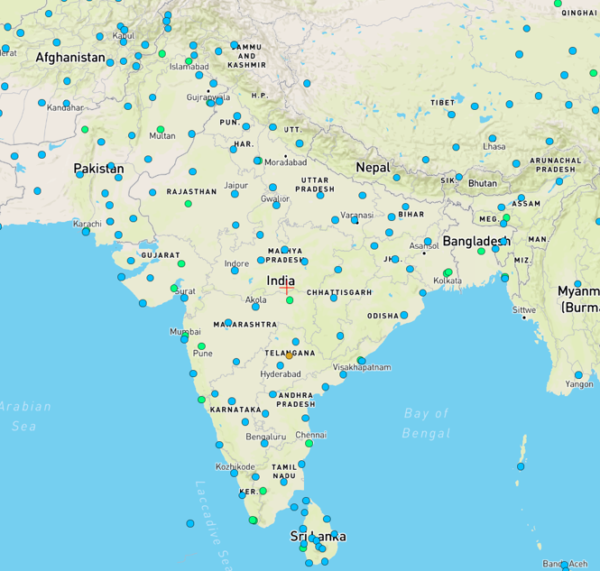

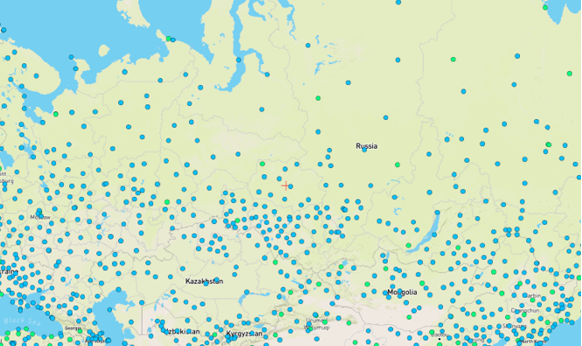

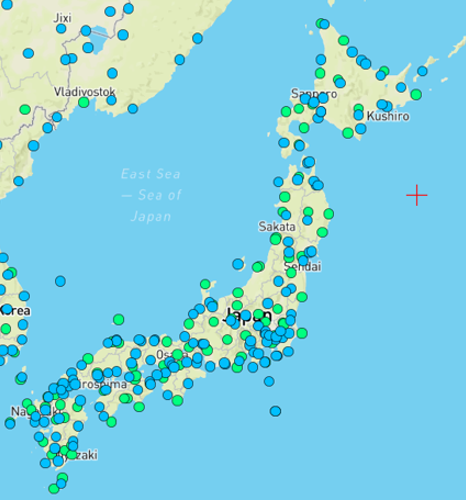

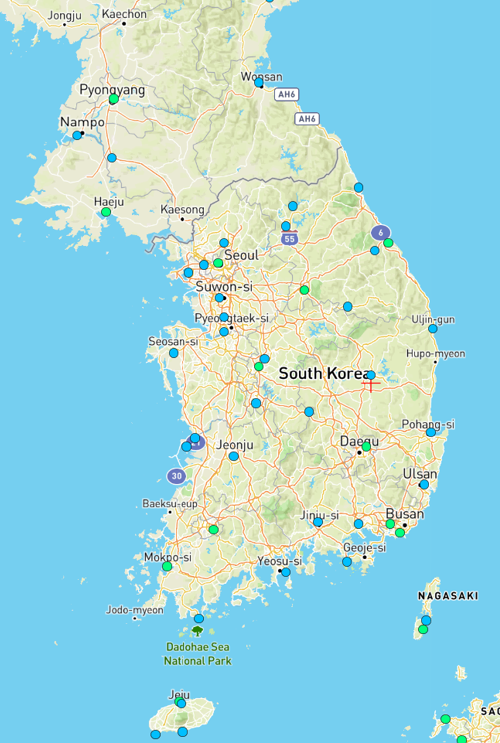

We show below maps of weather station of most of location worldwide.

Europe :

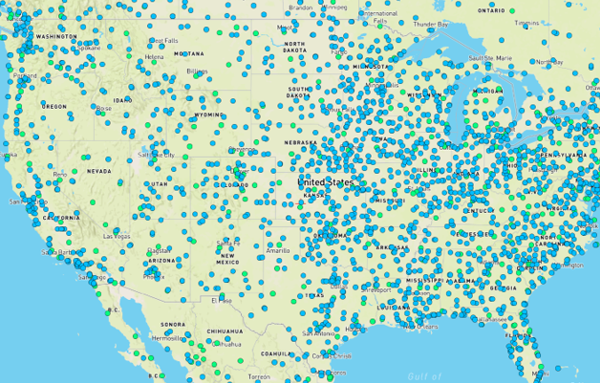

USA :

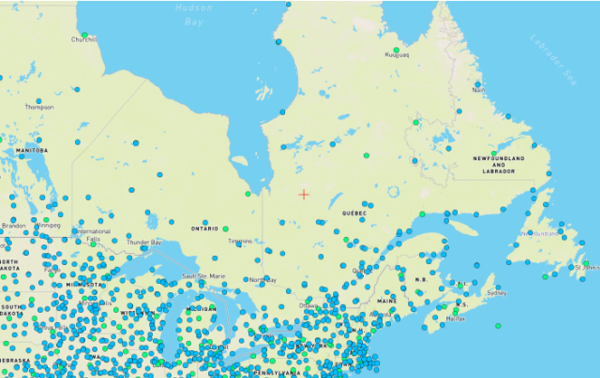

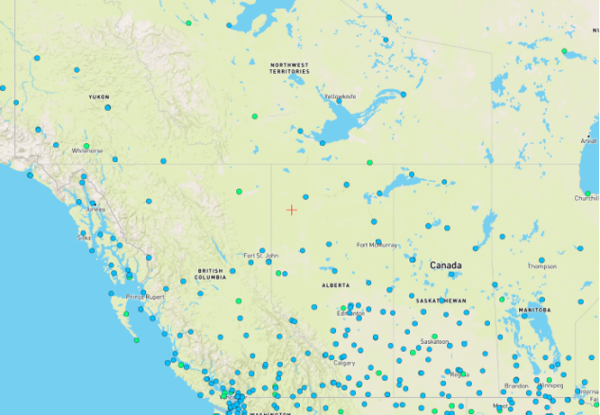

Canada :

Mexico :

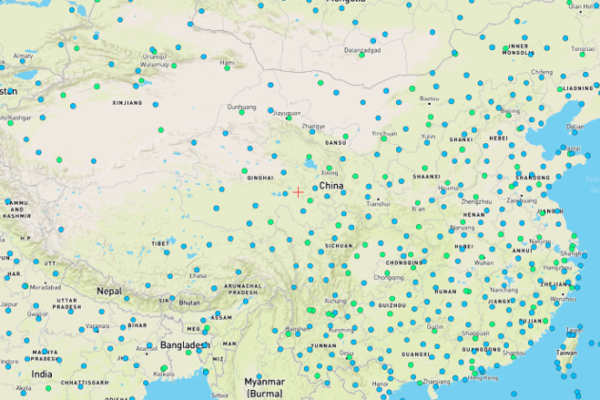

China :

Turkey and MENA Countries :

India :

South East Asia :

Russia :

Japan :

Korea :

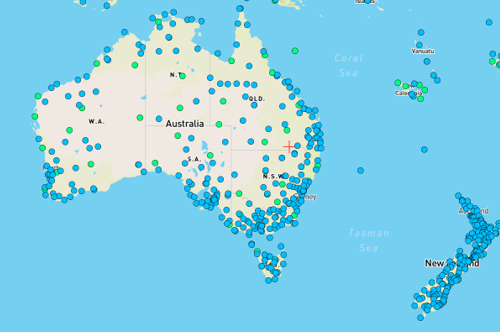

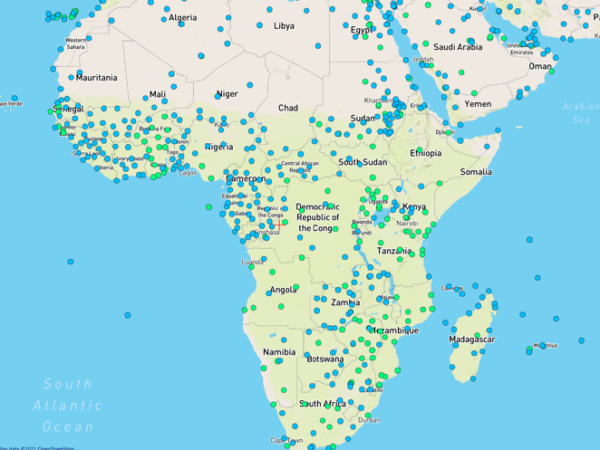

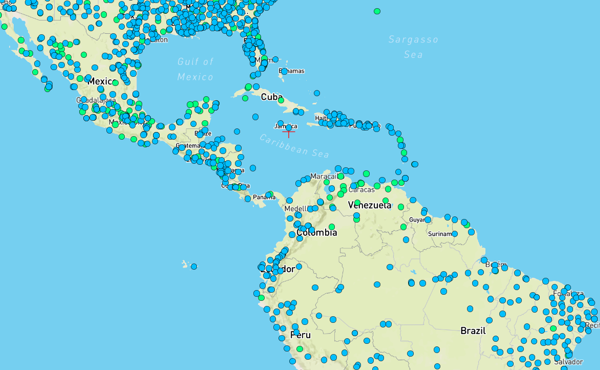

Australia and New Zealand :

Africa :

Central America :

South America :

For more details : https://meteonorm.com/

Climate change model

According to GPS coordinates of the greenhouse, Hortinergy displays in the report a typical year on an hourly basis including weather parameters, such as temperature, relative humidity, wind and solar radiation.

How does it work ?

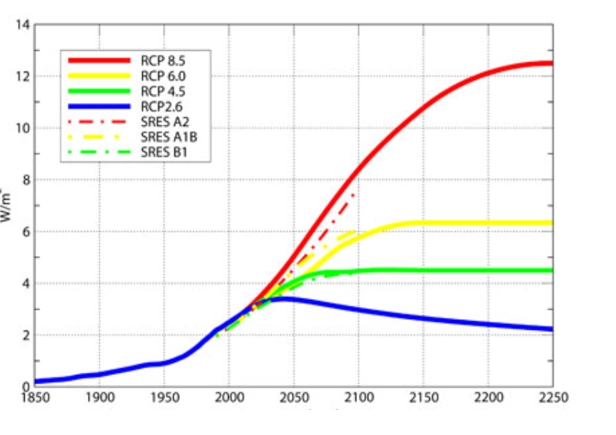

A Representative Concentration Pathway (RCP) is a greenhouse gas concentration and emission adopted by the IPCC. In order to assess these pathways, a number has been set up, based on the planet’s radiative balance.

Radiation balance (W/m²) = (solar radiation received) – (infrared radiation re-emitted)

The higher the value of radiation balance is, the less energy the planet re-emits, thereby keeping it into the atmosphere.

What are the Hortinergy parameters ?

With Hortinergy, it is possible to compare scenarios (RCP 2.6 – RCP 4.5 – RCP 8.5) of your installation.

For more details : http://sedac.ipcc-data.org/ddc/ar5_scenario_process/RCPs.html

Greenhouse type and covering

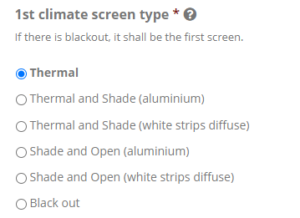

Screen types

A screen works as a curtain which can be installed vertically or horizontally. It aims to regulate inner temperature and humidity, reduce heat losses and control solar radiation, whatever the external climate surrounding the greenhouse.

What are the Hortinergy parameters ?

Transparent thermal screen : the major aim is to reduce energy loss. For instance, in order to maintain inner temperature during dark and cold period, it is deployed, thus keeping heat and radiation.

Hereunder a greenhouse composed with a transparent screen.

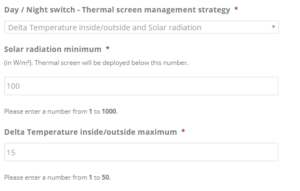

Thermal screen can be regulated according to 2 parameters:

- External solar radiation

- Temperature difference between outside and inside

During the night, morning, evening or cloudy days, when the incoming solar radiation is below 100 W/m², it is deployed to reduce heat losses and to let the solar radiation get in. On the other hand, when the incoming solar radiation is above 100 W/m², the thermal screen is undeployed.

As regards the temperature difference between outside and inside, the screen is deployed if the difference is higher than the setting and undeployed if the difference is lower

For tomato crop, standard values for a temperate climate such the Netherlands are:

- External solar radiation: 100 W/m²

- Temperature difference between outside and inside

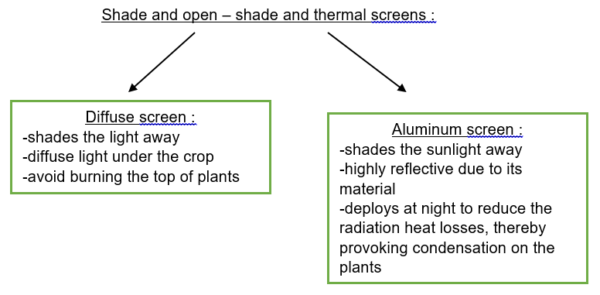

Shading screen : it is used to reduce direct radiation and the overall light level in the glasshouse to reduce overheating and to avoid burning leaves.

There are 2 types of materials for shade screen:

- aluminum

- white strips diffuse

There are also 2 types of structure for shade screen:

- open: space is open between shade strips -> good for ventilation, limited thermal effect

- closed: high thermal effect, chimney is required for ventilation

Hereabove a thermal and shading screen inside a greenhouse in northern Europe.

For instance, when incoming solar radiation is above 500 W/m², the shade screen is deployed.

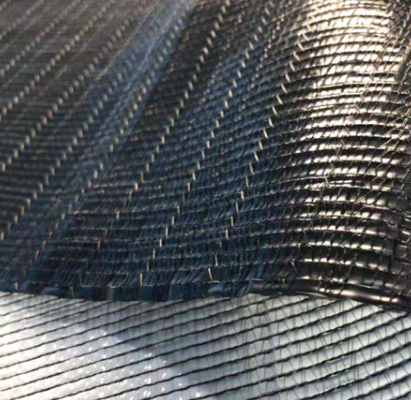

Hereunder a shade and open screen with aluminum strips.

With an open shading screen, a natural ventilation of your greenhouse is possible. However, as regards the closed shading screen, a chimney is required to get a natural ventilation.

Hereunder an example of thermal shading screen with a chimney :

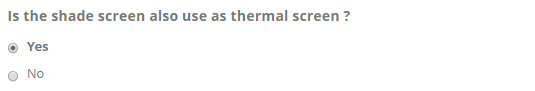

With Hortinergy, in order to choose the shade and thermal screen, you may tick the box yes to the question following question :

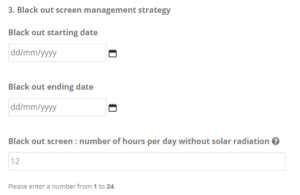

Black out screen : this screen prevents the plants from incoming solar radiation, from 99 to 100%. It is mostly used for the control of photoperiod and the prevent of light pollution to ensure an ideal growth of cannabis crops and ornamental plants.

Let’s take as an example the crop of cannabis, which needs 12h of lighting a day.

In summer, the day light period is higher than 12h, therefore blackout screens are deployed to day length to 12h in the greenhouse

In winter, the day light period is lower than 12h, therefore assimilation lighting is required to reach 12h. Then black out screen is required to prevent the environment from light pollution. Thereby, the black out screen is pulled when light intensity is below 20 W/m².

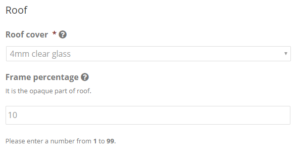

Greenhouse cover

Hortinergy offers you the possibility of choosing several solutions of greenhouse cover. Hereunder the two parameters used for roof and vertical faces :

Covers :

-4mm clear glass

-4mm clear glass 1AR coating

-4mm clear glass 2AR coatings

-4mm diffuse glass

-4mm diffuse glass 1AR coating

-4mm diffuse glass 2AR coatings

-6mm clear glass

-double inflated plastic film

-double glazing with thermal break

-double inflated ETFE

-double glazing

-low-E 4mm clear glass

-ETFE

-glass and ETFE

-single plastic film

-polycarbonate 8mm

-polycarbonate 10mm

-polycarbonate 16mm

-polycarbonate 32mm

-PMMA 16mm

-corrugated transparent PVC

-waved polycarbonate

-retractable plastic cover

-opaque (5cm insulation)

-opaque (10cm insulation)

-opaque 33% (5cm insul) – clear glass 66%

-opaque 50% (5cm insul) – polycarbonate 6mm (50%)

-opaque 50% (5cm insul) – polycarbonate 16mm (50%)

-opaque 50% (10cm insul) – polycarbonate 16mm (50%)

-polycarbonate 8mm opaque

-partition wall

Roof cover selection is automatically duplicated to the 4 vertical covers.

Gable cover selection is automatically duplicated to all other 3 vertical covers.

Length 2 cover selection is automatically duplicated to Length 4.

Frame percentage :

It is the opaque part of the roof, that is not transparent. It is usually 10% for glass greenhouse and 8% for plastic greenhouse.

User can modify manually its selection.

Orientation

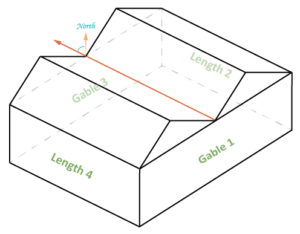

How to set up greenhouse dimensions ?

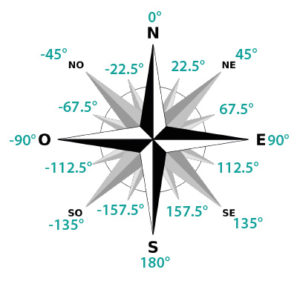

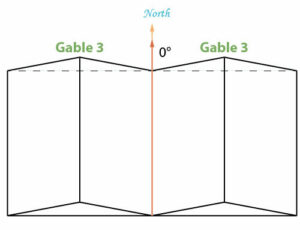

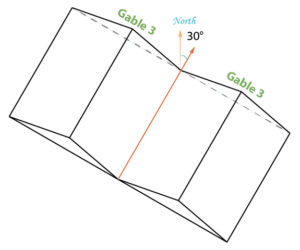

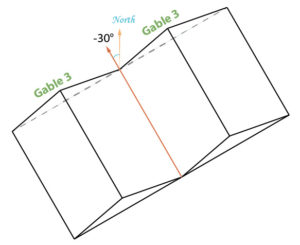

Hereunder the orientation setup of a greenhouse :

-Gable 1 : South wall.

-Gable 3 : North wall.

-Length 2 : East wall.

-Length 4 : West wall.

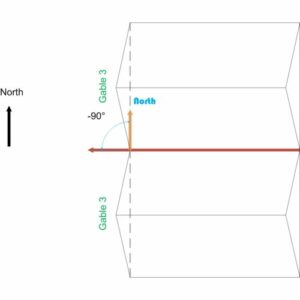

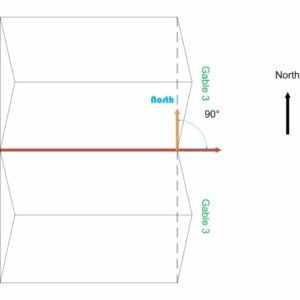

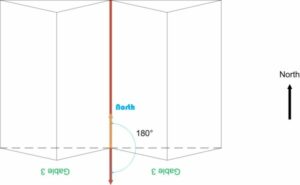

Orientation is based on gutter axis or Gable 3. For instance, it is negative if Length 2 is towards North-East, and positive if Length 2 is towards South-East.

Examples :

If Gable 3 is perfectly north-facing, then your greenhouse’s direction in degrees will be 0. It also means that Length 2 is totally east-facing, while Length 4 is west-facing.

If Gable 3 is west-facing, then your greenhouse’s direction in degrees will be -90. It also means that Length 2 is north-facing, while Length 4 is south-facing.

If Gable 3 is east-facing, then your greenhouse’s direction in degrees will be 90. It also means that Length 2 is south-facing, while Length 4 is north-facing.

If Gable 3 is perfectly south-facing, then your greenhouse’s direction in degrees will be 180. It also means that Length 2 is west-facing, while Length 4 is east-facing.

If Gable 3’s direction is N-30°E, then Length 2’s direction is N-120°E and Length 4’s one is N-60°W.

If Gable 3’s direction is N-30°W, then Length 4’s direction is N-120°W and Length 2’s one is N-60°E.

Greenhouse types

Hortinergy offers you the best solution of greenhouse type for the greatest optimization of your installation.

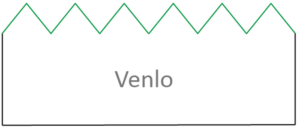

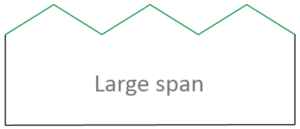

Hereunder the greenhouse types :

–Venlo greenhouse : fitted with glass, polycarbonate or ETFE. Usefull for large projects. Span width : post to post distance 8 or 9.6m / gutter to gutter distance 3.2 or 4m. This type of greenhouse is cheaper than large span one.

–Large span greenhouse : fitted with glass, ETFE or polycarbonate. Suitable for small-area planting. Span width : from 6 to 17m.

–Flat arch and gothic greenhouses : fitted with plastic. Suitable for large or small area planting.

Crop and climate regulation

Climate settings

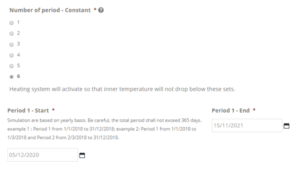

Each crop shall have its own climate conditions to grow in a good environment. In response to that, Hortinergy takes into account 3 settings : heating, humidity and vents opening.

Heating system will be activated to prevent the inner temperature to drop below these settings. Then, due to insolation, inner temperature could go up fast. In that time, vents opening settings will be turned on to cool the inside of the greenhouse.

When humidity is higher than the settings, vents, active ventilation or dehumidification are activated.

Heating settings

Heating system is turned on when temperature will not drop below the required inner temperature of the greenhouse.

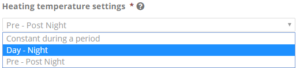

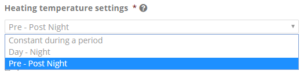

Hereabove the different temperature regulation modes :

- Constant during a period

First, the “Constant during a period” option, as indicated, means that the minimum temperature to heat the greenhouse during a day will be the same. However inner temperature can be higher due to external clilmate. Mostly used for pot plants.

2.Day-Night

Then, with the “Day-Night” option, you need to insert the minimum required inner temperatures during the day and night. It is based on two parameters : the delta temperature inside/outside and the solar radiation, which will be used to deploy the thermal screen. Daytime setpoint temperature is usually higher than nightime one, so as to ensure a good growth of the crop and a better return on energy saving. Mostly used for the crop of cannabis.

3.Pre-Post night

Finally, the “Pre-Post night” option is used to split the night in two. For instance, if the night lasts 8 hours, it will be composed of a 4 hours pre-night, followed by a 4 hours post-night. Pre-night setpoint temperature is usually lower than post-night one. Mostly used for tomato crop.

The duration of a period is set by the customer. For instance, a period may be from 12/01/2021 to 13/01/2021 or from 15/03/2021 to 18/09/2021. Moreover, in one year, 6 periods may be chosen.

Crop settings

Crop library

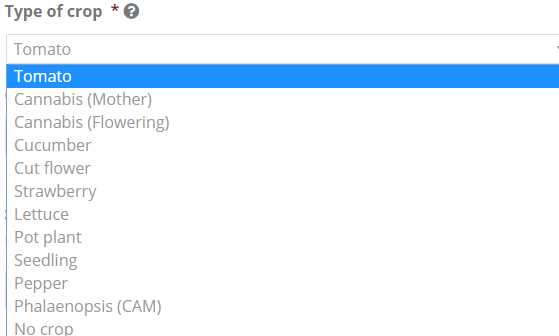

With Hortinergy, it is possible to choose a crop among others, thanks to its library.

Crop transpiration :

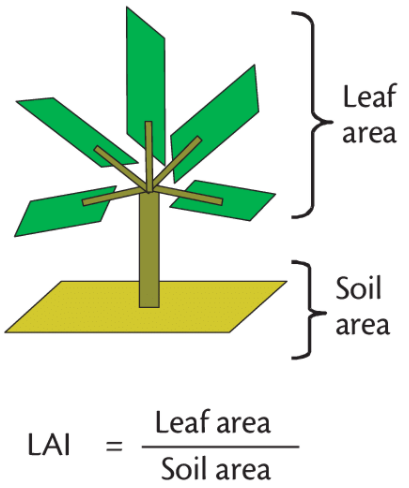

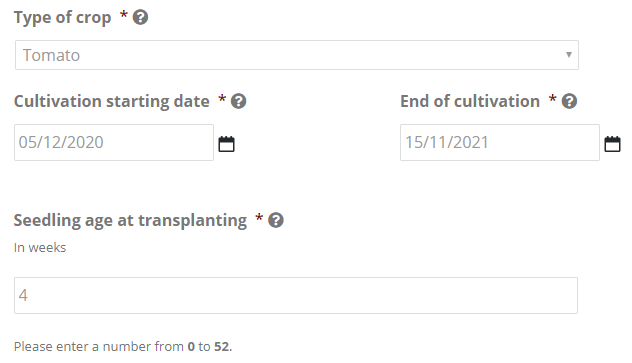

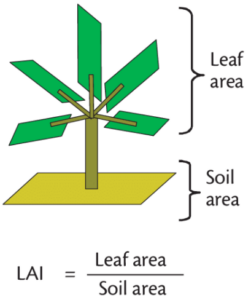

Crop transpiration is calculated according to Penman-Monteith equation.based on crop type, LAI (Leaf Area Index), light (solar/supplementary), temperature, humidity and air velocity.

The higher solar radiation and inner temperature are, the higher crop transpiration is. But the higher relative humidity is, the lower crop transpiration is.

LAI is the link between leaf area and soil area covered by the leaves. The higher LAI is, the more important crop transpiration become.

The LAI is pre-defined in Hortinergy based on the type of crop, its transplantation date and seedling age. Cultivation starting and ending dates are also required.

The seedling age at transplanting is the age, in weeks, of seeds before they get transplanted inside a greenhouse. The older seeds are, the faster crop growth and LAI will be, which means a transpiration more significant in a short period of time.

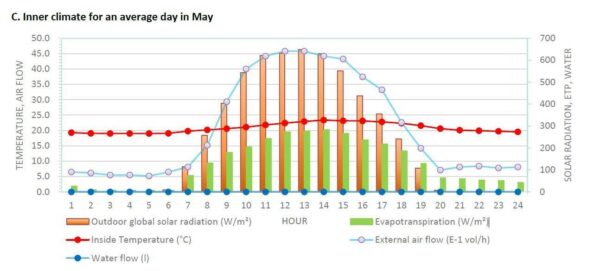

Results

Hortinergy shows the water transpiration by the crop (that is more /less than irrigation needs-substrate transpiration (that is very low)).

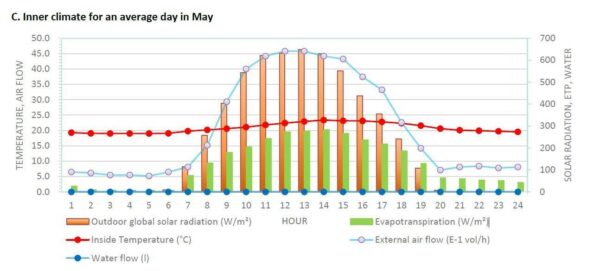

Evapotranspiration is the water transpiration by the crop. It is put in W/m² to show direct relation with solar radiation. The higher solar radiation and inner temperature are, the higher crop transpiration is.

Evapotranspiration for 1 l water = approx 0.68 kWh energy (depending on temperature)

These results are accurate for tomato in winter, but are theoretical in peak summer when other factors can limit transpiration (hydric stress, leaf temperature too high…).

Heating, cooling systems and assimilation lighting

Supplementary lighting

Principle

Supplementary lighting is used to increase the total daily light. Light intensity, spectrum and duration affect several plant growth and processes. There are several reasons for providing supplementary lighting:

- When natural light is scarce, it helps to increase yield and production quality such as tomato …

- Supplementary lighting is also applied for day length control in ornamental crops.

With Hortinergy, you have two types of lighting systems : the first one is called “High Pressure Sodium” (HPS) and the second one “Light Emitting Diode” (LED).

LED light :

Pros :

-long life expectancy

-almost no excess heat, which allows it to be placed very close to plants

-low operating/maintenance cost

-high yield per Watt

Cons :

-high initial cost

HPS light :

Pros :

-low initial cost

Cons :

-the high intensity of light from this lighting system generates a lot of heat

-additional cooling system is needed

-high operating cost

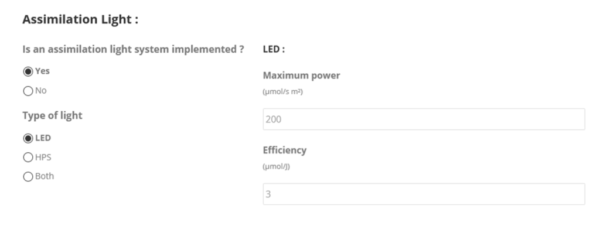

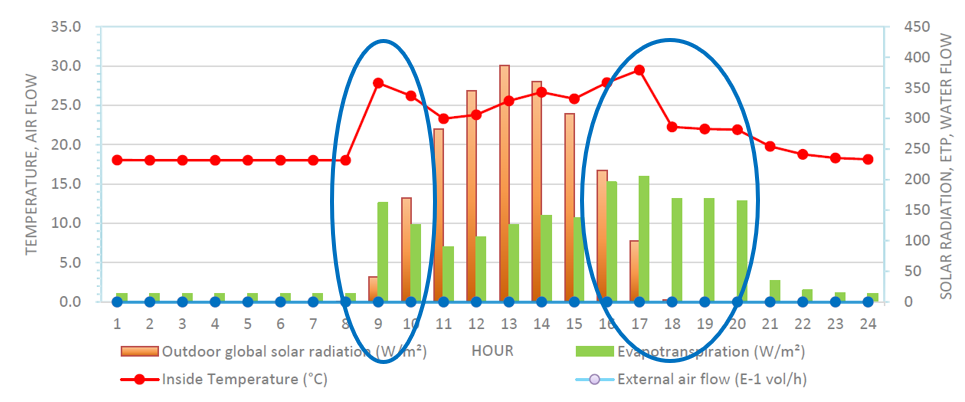

Input parameters with Hortinergy

Input parameters are:

- LED and HPS specification: lighting intensity, efficiency…

- Regulation setpoints:

- Day Light Integral (DLI) and minimum hours of ‘’night’’ per day,

- or fixed monthly schedule above which solar radiation intensity lighting is switched off.

You first define you lighting system:

Then you define the regulation settings:

Results

Hortinergy simulates your project during one year like a virtual greenhouse. Outputs are :

- Solar radiation transmitted by the transparent cover and reaching canopy,

- Assimilation lighting required according to regulation setpoints (mol/m²/day):

- Electricity consumption,

- Impact on the inner climate and energy consumption: heating, cooling, dehumidification.

The reports are:

- a pdf document with typical days and monthly summary tables

- an Excel file with hourly data for deeper analysis.

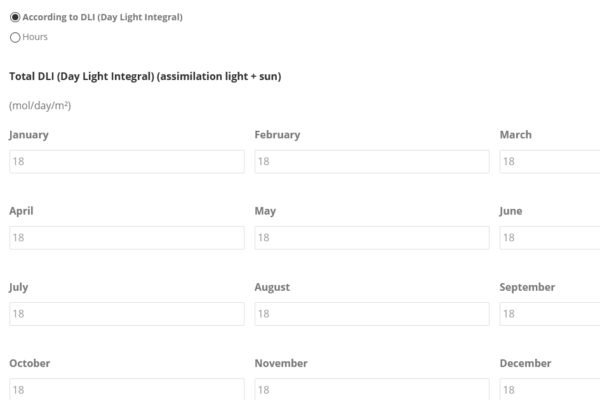

Solar radiation reaching canopy and additional assimilation lighting required

Hortinergy simulates on hourly basis the solar radiation reaching canopy and the additional assimilation lighting required to reach the DLI.

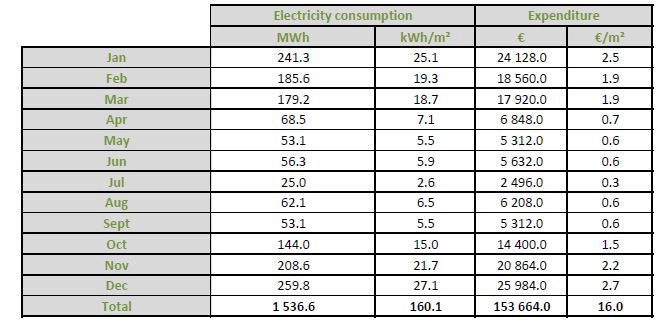

The example below shows a monthly summary.

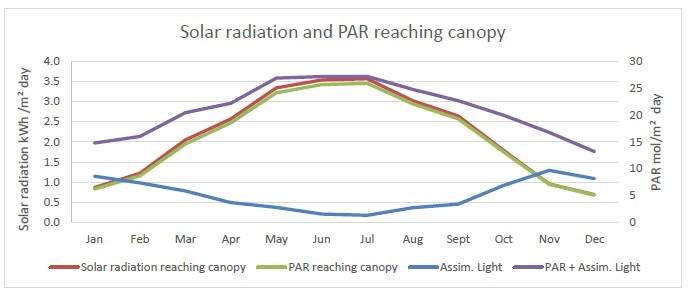

Impact on the inner climate and energy consumption (heating, cooling, dehumidification)

Hortinergy models the impact of assimilation lighting on the inner climate and energy consumption (heating, cooling, dehumidification).

The example below shows the crop transpiration and a higher inner temperature when HPS assimilation lighting is switched on from to 9 to 11 AM and 4 to 9 PM to reach DLI.

Electricity consumption and expenditures

Hortinergy shows also the electricity consumption and expenditures.

Heat production

Hortinergy offers two heat production settings :

– Hortinergy’s estimate

– User defined (advanced parameters)

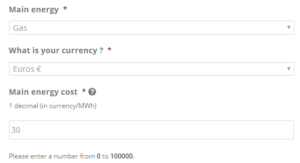

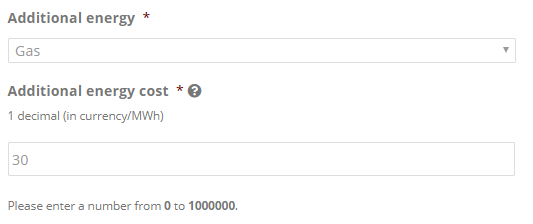

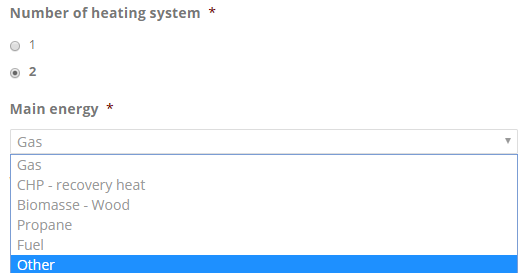

On the one hand, Hortinergy’s estimate takes into account one energy system, accompanied by its type and cost, considering also an efficiency of 95% of the boiler. Max power of the boiler is also calculated by the software. With it, you might choose one main energy and its cost, followed by its currency.

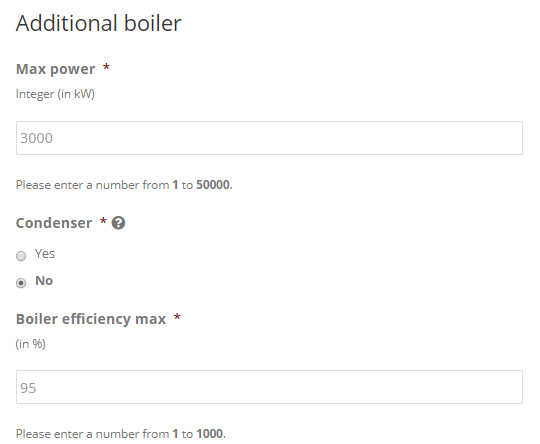

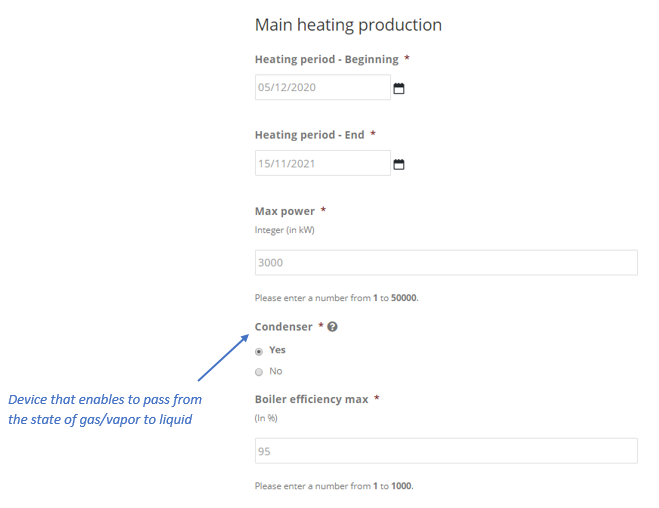

On the other hand, the option user defined puts forward two energy systems. Each of them can have different types of energy and advanced parameters : heating period, the maximum power that will be used, the presence of a condenser or not and the boiler efficiency.

As said before, for each system, you have the choice between several types of energy. The most common ones are gas and biomass.

If there is not any open buffer and the demand is superior than the maximum energy power of the main system, the second type of energy is turned on. In case there is an open buffer, if the request is superior than the maximum energy power of the main system, then it will unload. Once it is void, the second energy is engaged to replace it.

Heat pump enters COP as an efficiency and chooses electricity. For instance, a COP that is equal to 4 represents an efficiency of 400%.

CHP is based on heat production efficiency, generally set at 44%. Besides, it also calculates overall gas consumption.

Regarding water buffer tank, there are two utilisations : the first one with gas boiler and the second one with biomass/waste heat boiler.

Gas boiler : the container stores the heat energy generated in the gas boiler during daytime CO2 supply, when heating demand is the lowest.

Waste heat boiler : it uses the heat in flue gases from combustion processes or hot waste air flows from industrial processes to generate hot water.

For more information about water buffer tank, you can have a look at our support documentation.

Distribution efficiency :

It represents the heat losses in the transport between the boiler and the greenhouse. By default value, these losses amount to 5%, which represents a distribution efficiency of 95%.

Closed or sealed greenhouse

Principle

A greenhouse is « sealed » or « closed » when there is not any air exchange with outdoor air.

In order to maintain inner temperature and relative humidity of a closed greenhouse, heating, cooling and dehumidification systems have to be implemented, so that crop production can be realized in good conditions.

Cooling and dehumidification are usually done via heat-exchangers in the greenhouse. This enables higher CO2 concentrations in the greenhouse and consequently a higher crop production rate.

In some cases, a sealed greenhouse is linked to underground aquifer or very large buffer. During sunny or hot days, the surplus heat is stored in the short term (diurnal) buffers or long term (seasonal) storage in underground aquifers. During nightime or cloudy days, warm water from the aquifer or buffer heats the greenhouse.

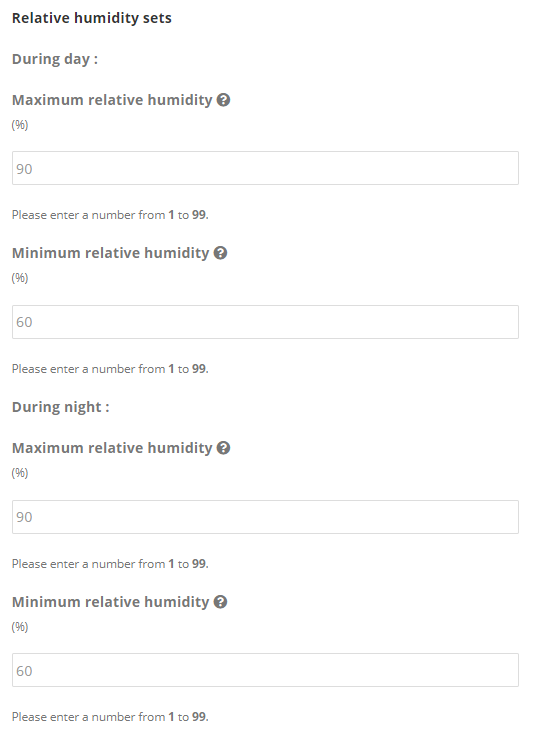

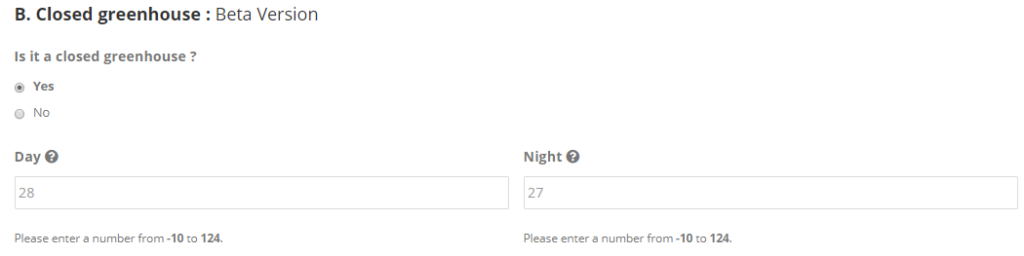

What are the Hortinergy parameters ?

The maximum temperature and humidity settings, such as relative humidity and humidity deficit, have to be filled.

Once inner relative humidity is exceeded by relative humidity sets, latent cooling is engaged.

Cooling system will be activated so that inner temperature will not go above this set.

For instance, even though solar radiation is expected to rise the inside temperature significantly, the cooling temperature, set at 28°C during the day will prevent from exceeding this temperature.

Results

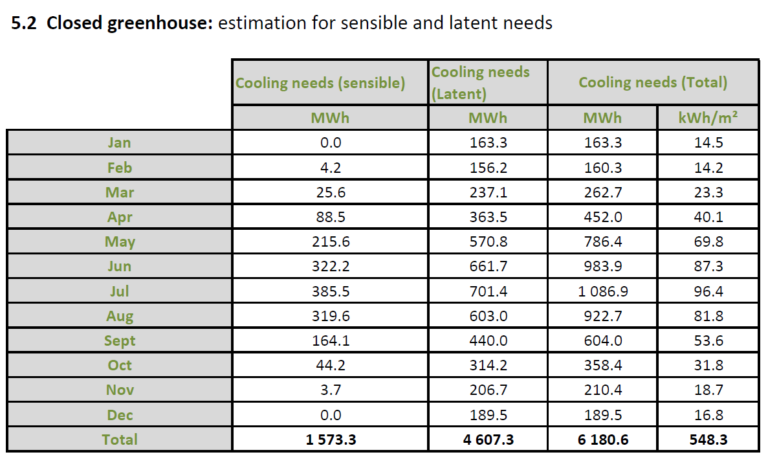

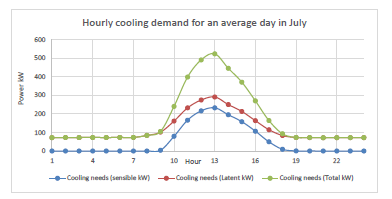

In turn, Hortinergy calculates the sensible and latent cooling needs to control the greenhouse inner climate (temperature and relative humidity).

Sensible cooling : it is the process in which only the sensible heat of the air is removed so as to reduce its temperature, without any change in the moisture content of the air.

Latent cooling : it is the capacity to remove the moisture from the air, without any change in the temperature of the air.

Based on the results, the engineer can design the best HVAC system and calculate energy consumption.

Hereunder a typical example from a report. Results are shown in three different ways.

First, as a monthly synthesis.

Then, as an hourly synthesis of a typical month.

Finally, hourly values during a typical year are referenced as OX-24h.

Sensible heat : it is the amount of heat exchanged, without any physical stage transition, between several bodies forming an isolated system.

Latent heat : it is the amount of energy exchanged between an object and its environment during a change of state, i.e. during solidification, fusion or boiling.

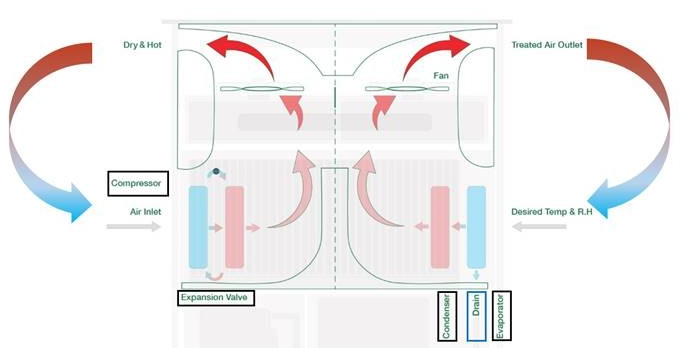

Thermodynamic dehumidification solution

Humid air is taken in from the greenhouse, through the side panels, and travels over the cooling coils, which circulate the cold refrigerant. Then, water vapor condenses as it comes into contact with the cold coil. The liquid water that forms is channeled out of the unit. This distilled water may be collected and reused.

The dry air is then transported over hot coils, made hot by compressed and heated refrigerant. Passing through this second coil heats the air back up to greenhouse temperature. The dry air is released through the top of the unit, hitting the canopy, which spreads the dry air above the plants.

This system is more suitable in cold regions than hot ones.

For more details : http://www.drygair.com

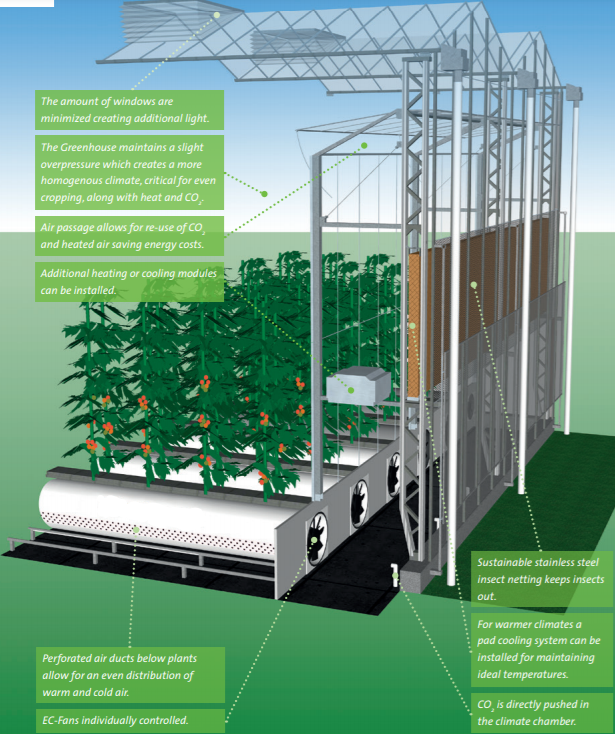

Semi-closed greenhouse

How does it work ?

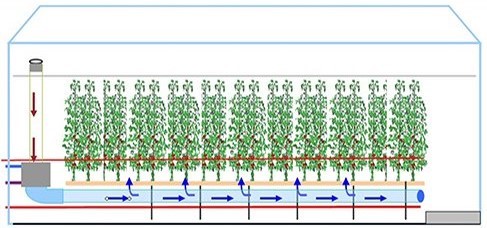

The corridor, located on the outer gable of the greenhouse, uses outside air for dehumidification and cooling. Thus, the corridor is used to mix inner air with external air. This phenomenon represents the air treatment of semi-closed greenhouses, mostly used for Venlo glass (Kubo, Van der Hoeven, Richel, CERTHON…) and plastic (CMF, Richel…) ones.

This system aims to :

-dehumidify the atmosphere of the greenhouse by renewing and drying out the air inside, due to outdoor air (during the night and in the morning)

-cool dry inner temperature with pad cooling system, on external side of the corridor

-reduce the amount of harmful insects, thanks to overpressure

-control the climate of the greenhouse avoiding the gap of temperatures

-optimize the use of energy and CO2

Heating system is composed of :

-air ducts below crops’ gutters for the diffusion of warm/cold air

-low temperature network (30-40°C) placed in vegetation

-high temperature network (70-80°C) placed on the ground to ensure heating

Cooling system could be composed of :

-pad and fan system using evaporative cooling

-fog system using evaporative cooling

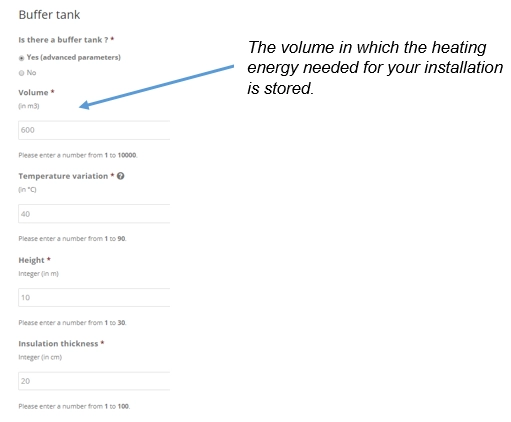

Water buffer tank

Imagine a battery of energy that is ready to be distributed at any time.

There are two utilisations of a water buffer tank : the first one with gas boiler and the second one with biomass/waste heat boiler.

How does it work ?

Gas boiler : the container stores the heat energy generated in the gas boiler during daytime CO2 supply, when heating demand is the lowest.

Waste heat boiler : it uses the heat in flue gases from combustion processes or hot waste air flows from industrial processes to generate hot water.

What are the Hortinergy parameters ?

The volume of a buffer tank is generally around 300 m³ per hectare.

As regards temperature variation, it is calculated according to the difference between the heat production temperature and the heat emission temperature of the boiler.

For instance, if the heat production of the boiler is 85°C and the heat emission temperature is 60°C, the temperature variation equals 85-20=65°C.

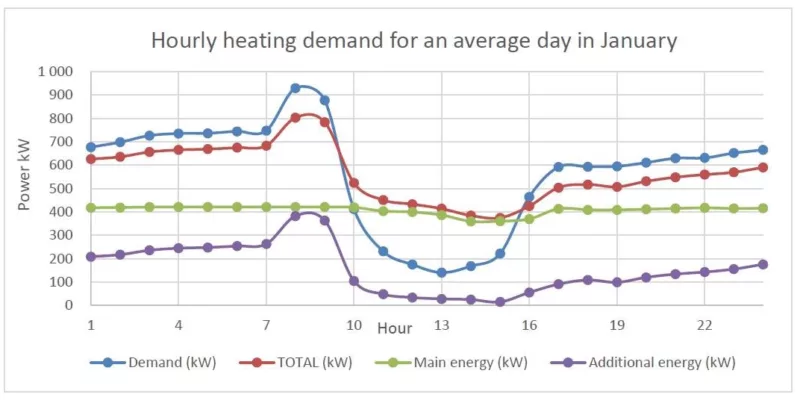

Hereunder a case study of biomass boiler’s heating demand, the buffer tank running on 410 kW.

On the one hand, the periods during which heating demand is under the main energy allow the water buffer tank to warm up. For instance, in this graphic, the water buffer tank is storing heat energy from 10 am to 3.30 pm.

On the other hand, during the rest of the day, when heating demand is above the main energy, water buffer tank is providing continuously heat energy to the system in which it is installed.

Fog system

As the pad and fan system, it uses evaporative cooling method to cool down greenhouse temperature.

How does it work ?

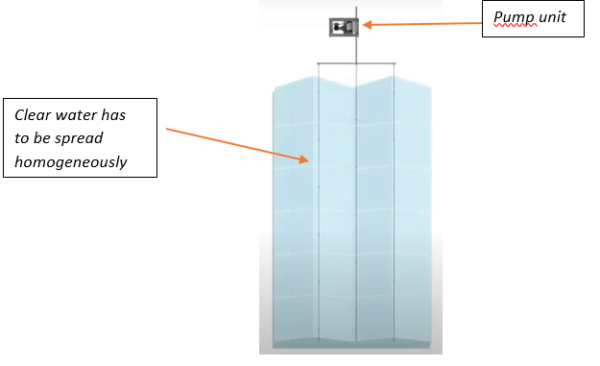

Clear water is pushed through a stainless steel nozzle. Then, the particles of this water are evaporated before they reach the crops. This system works with a pump unit fitted with a high pressure pump. Nevertheless, it has to be mounted at the right height, according to climate conditions. Lastly, nozzles should be mounted alternately for a homogeneous coverage.

What are the Hortinergy parameters ?

Pros :

-natural cooling (it regulates temperature to a very high extent in situations where ventilation is not enough, thereby decreasing inner temperature when needed + less C02 will get lost and a higher amount will be available for crops to grow)

-minimal water use (thanks to the regulation of temperature and humidification)

-optimal humidity

-small droplets (micron) lead to a higher droplet density

Cons :

-this technology hugely depends on climatologic conditions. Indeed, if it is too wet, the system does not work effectively.

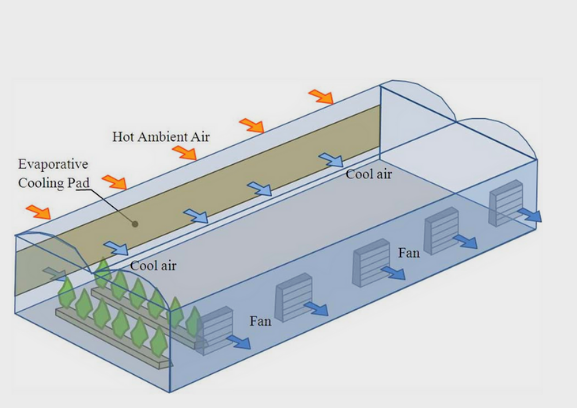

Pad and fan system

How does it work ?

Pad and fan system cools down greenhouse temperature, using evaporative cooling (absorption of a large amount of heat, by the water, in order to evaporate). During hot summer days, it is an effective way, for small greenhouses, to cool, putting plants in the best climate conditions. Besides, this system uses exhaust fans to absorb air from outdoors into the greenhouse. Firstly, the air is blown through the pad, which constantly evaporates water, creating a cooling effect. Then, the fans blow the cool air into the greenhouse, leading to an overall drop in temperature.

Some greenhouses do require cooling at night, mostly in tropical regions. However, wet pad and fan system may not provide the desired results in tropical regions, where absolute humidity is often high during the night.

Indeed, when conditions outside are humid, pad and fan system loses effectivity and provides a much lower cooling capacity. This is because evaporative cooling relies on the difference between outdoor and indoor conditions.

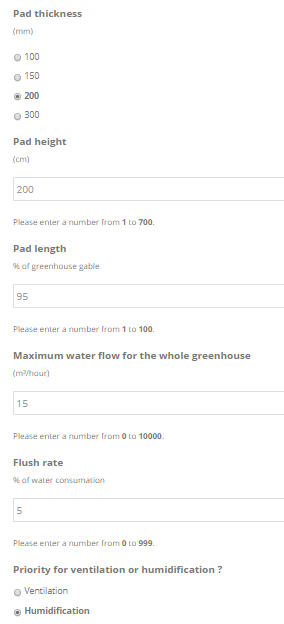

What are the Hortinergy parameters ?

Pros :

-it keeps the greenhouse’s inner temperature cool permanently, providing lower temperature even during hot periods of the year

-it decreases temperature and increases humidity, thereby reducing transpiration of plants

Cons :

-the distance from pad to fan reflects uneven cooling pattern

-if the system operates unceasingly, the growth of crops will be probably uneven

-it is not effective in areas with high humidity (ex : coastal areas)

Glossary

Hereunder a pair of words that will certainly help you to better understand Hortinergy’s parameters.

Glossary A-E

Absolute humidity : actual water vapour content of air. Units are either in g/kg, g/m³ or kPa.

Absolute humidity difference inside/outside : AH inside – AH outside à in g/kg or g/m³, determines the amount of moisture expelled by ventilation.

Adiabatic cooling : process of cooling down air with very fine droplets of water. The variation of enthalpy is void, because of the same amount of latent heat created and energy withdrawn from the air.

Assimilation lighting : used to adjust the light intensity of a greenhouse to the desired level during the darkest days of the year.

Black out screen : under hot conditions, shading prevents the plants from heat to 99%, thus letting just 1% of incoming solar radiation reach them. It is mostly used for the control of photoperiod and the growth of cannabis crops and ornamental plants.

Crop transpiration : mutation of the water from the crop to the air, in the vapour phase.

Distribution efficiency : heat losses in the transport between the boiler and the greenhouse.

Enthalpy : energy content of dry air expressed in kJ / kg. Based on two components : sensible heat (energy required to raise the temperature of a substance) and latent heat (energy required to evaporate the present water content).

ETFE : a plastic film that is clearer and lighter than glass. Even though the lifespan of this product is higher, it stays noisy while dealing with wind and rain.

Evaporation : conversion of liquid water to water vapour, due to the removal of water from evaporating area.

Glossary F-L

Fog system : as the pad and fan system, it uses evaporative cooling method to cool down greenhouse temperature. Clear water is pushed through a stainless steel nozzle. Then, the particles of this water are evaporated before they reach the crops. This system works with a pump unit fitted with a high pressure pump.

Humidity deficit : difference between the maximum water vapour content at the actual temperature and the actual water vapour content. Unit in g.kg or g/m³.

Latent cooling : it is the capacity to remove the moisture from the air.

Latent heat : it is the amount of energy exchanged between an object and its environment during a change of state, i.e. during solidification, fusion or boiling.

Leaf Area Index (LAI) : it characterizes plant canopies (aboveground portion of a crop or plant)

Glossary M-S

Pad and fan system : pad and fan system cools down greenhouse temperature, using evaporative cooling. The pads are installed on one side of the greenhouse, with the fans on the other side. These fans blow air from inside to outside, absorbing outdoor air through the pad. Thanks to the wet pads, dry outdoor air becomes colder and more humid, ideal for the growth of plants.

PAR light : radiation with a wavelength in the range from 400 to 700 nm that is used by photosynthetic organisms in the process of photosynthesis.

Polycarbonate : plastic film presenting in two forms : a single layer and a multi layer. Here are the different features of polycarbonate in multi layer:

-for 8 or 10mm of polycarbonate thickness, 1 air gap with a double layer are used

-for 16mm of polycarbonate width, 2 air gaps with a triple layer are used

-for 32mm of polycarbonate width, 3 air gaps with a fourfold layer are used

Relative humidity : percentage of the saturated/maximum water vapour content at the actual temperature. RH = (actual water vapour content) / (maximum water vapour content) x 100.

Semi-closed system : a corridor, located on the outer gable of the greenhouse, uses outside air for dehumidification and cooling. Thus, the corridor is used to mix inner air with external air. This system uses also air tubes below gutters bringing air from the corridor to the crop.

Sensible cooling : it is the process in which only the sensible heat of the air is removed so as to reduce its temperature, without any change in the moisture content of the air.

Sensible heat : it is the amount of heat exchanged, without any physical stage transition, between several bodies forming an isolated system.

Shade and open screen : with its highly reflective quality and open structure ideal for ventilation, shade and open screen shelters plants from sunlight, which makes it suitable for shading in hot climates or to manage more sensitive plants.

Solar radiation : radiation coming from the sun on an area in the range from 1 and 1400 W/m², depending on location and season.

Glossary T-Z

Thermal screen : used to maintain inner temperature of the greenhouse, when the sunlight is weak. Indeed, in wintertime or at night, after being deployed, it is used to keep heat and radiation. On the opposite, it is able to prevent the greenhouse from radiation and heat during hot periods of the year.

Ventilation capacity : maximum volume of air exchanged by a fan in m³/h or m³/m².h.

Ventilation – natural/forced : used to exhaust heat and moisture in order to refresh the air within the greenhouse. Therefore, it is the exchange of inner air and external air of the greenhouse. Natural ventilation depends on wind, temperature differences and vents dimensions, while forced ventilation refers to technical methods such as fans and vents opening characteristics.

Ventilation rate : volume of exchanged air in m³/m².h or m³/h.

Vents : ventilation windows located in the roof or the side walls of the greenhouse.